VIKING VS-REDONDANT-FEEDLNB Redondant Parallèle LNB Système d'Alimentation

VIKING ETI-ADH-SMART-MANIFOLD (23659) Collecteur de distribution d'air automatisé Alimentation CC

Code produit: VIKING_VS-REDUNDANT-FEEDLNB

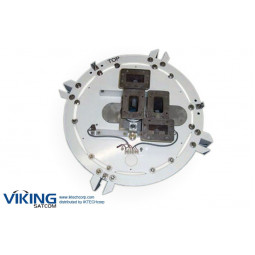

VIKING VS-REDUNDANT-FEEDLNB Redundant Parallel LNB Feed System

|

||||||||||||||

| Summary | ||||||||||||||

| VIKING VS-REDUNDANT-FEEDLNB

Redundant Parallel LNB Feed System

Overview New developments in high-order modulation schemes provide for significant numbers of programming channels using one satellite transponder. It is now apparent that a single LNB may support up to 100 channels in the High Density environments and even more where the programming is Standard Density. Further, modern satellites allow for using 3.7m and 4.5m prime focus antennas for commercial quality satellite programming acquisition. Because the failure of a single LNB can cause the loss of multiple channels, program providers are requiring a higher level of reliability with reference to LNBs. Before now, redundant LNB systems have been available mostly for antennas that use a sub-reflector (Cassegraine or other) type of feed system with the LNBs mounted on the hub at the back of the antenna. This is not ideal prime-focus antennas due to the bulk and weight associated with waveguide switches and other hardware. Parallel Feed System In order to provide 99.999 % reliability for LNBs and LNB power, we provide the Parallel Feed System for use on a Prime Focus Antenna. The Parallel Feed System (PFS) is unique in that it has two (2) identical feedhorns and LNBs with mechanical capability to align either (feedhorn) to the exact antenna Focal Point. The RSP 21250 Redundancy Switch monitors the primary LNBs for loss of RF output just as with the Backup Antenna System. However, concurrent with the command to switch the RF inputs from primary to backup LNBs, there is also a command to the Feedhorn Control Unit that mechanically moves the feedhorns so that the backup feedhorn assumes the primary, boresight position. The delay associated with repositioning the feedhorn is about three (3) seconds. Depending on the receiver authorization protocol this may or may not result in a momentary de-authorization of the receiver. A manual toggle switch on the Feedhorn Control Unit provides an override function for testing and is used to command the feedhorns back to the primary/backup position after the faulty LNB is replaced. The Feedhorn Control Unit also provides an alarm function to allow a monitor-and-control system to verify status and operations. RSP 2150 Redundancy Switch The RSP 2150 Redundancy Switch provides automated switchover for signal paths in the event of a failed LNB or Power Supply. An alarm is set on the front panel to indicate and isolate the failure. It also incorporates connectivity for communications to alert a facility M&C system if remote monitoring functionality is employed. LNB power is provided using internal dual power supplies, each with a separate AC power cord. This ensures that a power-supply failure will not cause signal loss. In addition, the new switch has a hot-swap feature for Power Module replacement, thus ensuring the overall system is not taken off-line, even for power supply repairs. The RSP 2150 sensing system monitors a user-preset RF input and commands a shift to the backup LNB if the input falls below the desired level. In case of D.C power interruption, it switches internally to the backup Power Supply. The internal delay associated with the switching process is on the order of just milliseconds from detected RF loss to restoration of Signal from the backup LNBs. VIKING VS-REDUNDANT-FEEDLNB Redundant Parallel LNB Feed System Features:

|

||||||||||||||

| Technical Specifications Diagram | ||||||||||||||

|